In today’s world of shrinking devices, every millimeter – and every milliamp – counts. Micro‑motors are becoming smaller, lighter, and more efficient than ever before. At the heart of this revolution? Micro‑magnets: tiny powerhouses that bring punch without bulk.

The Rise of Micro-Magnets

Micro‑magnets – often less than a millimeter in diameter – are tiny yet mighty. Made predominantly from high‑energy materials like neodymium‑iron‑boron (NdFeB) or samarium‑cobalt (SmCo), they deliver exceptional flux density in a minuscule form factor.

BJA Magnetics’ Micro‑Magnet™ fits this bill brilliantly: as small as 0.010″ in diameter with energy densities up to 52 MGOe, tight tolerances (±0.0003″), and biocompatible coatings – perfect for precision micro‑motor designs.

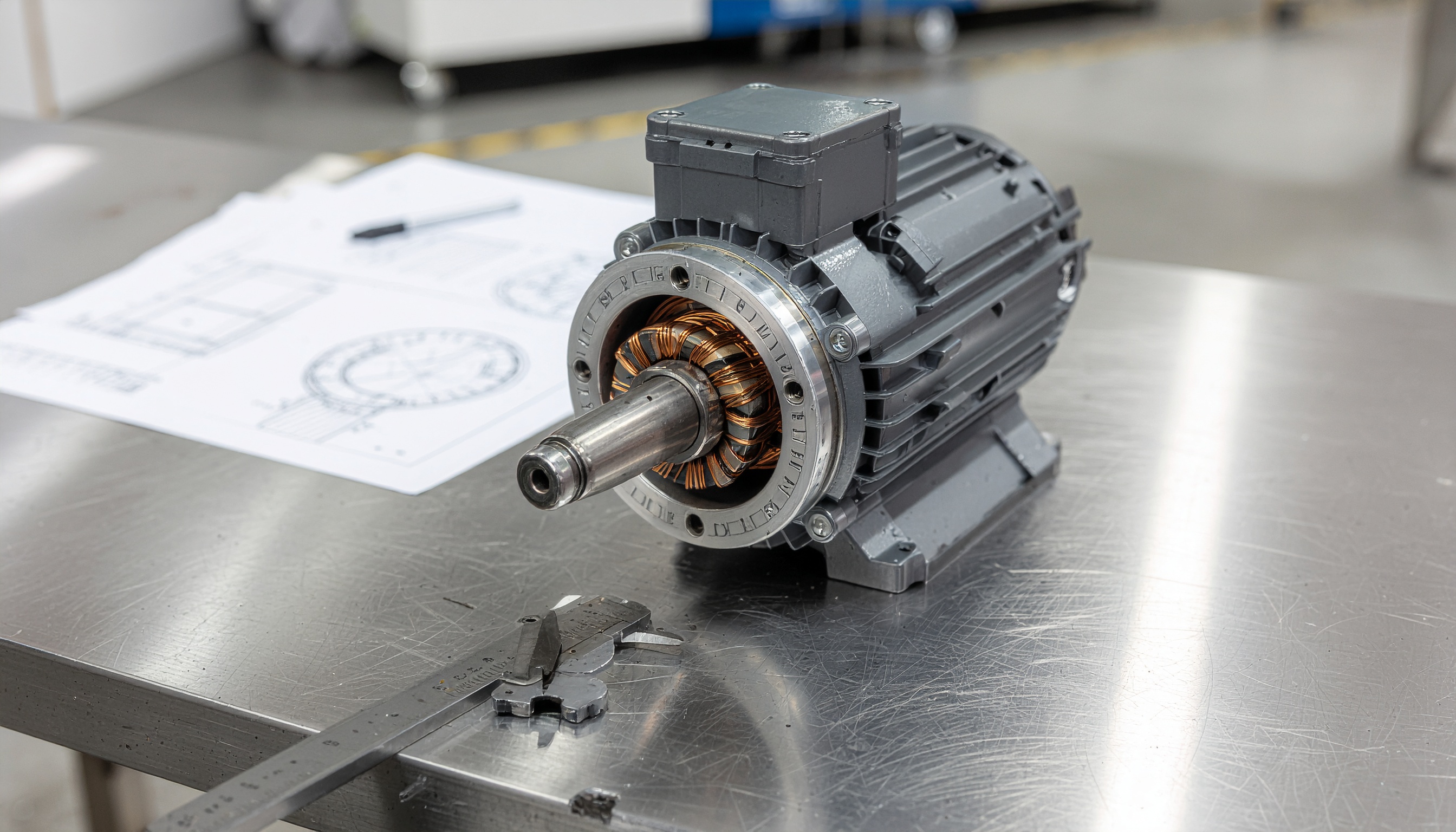

Why Magnets Matter in Micro‑Motors

Permanent magnet micro‑motors – whether brushless or slotless – depend on these powerful magnets for simple yet high-performance drivetrain designs. Because they eliminate the need for bulky electromagnetic windings, magnets enable micro-motors to be compact, energy-efficient, and responsive.

Rare-earth magnets, such as NdFeB, provide high torque and speed in a minimal size, while SmCo offers excellent stability at high temperatures – ideal for wearable health sensors or surgical tools.

Innovations at the Micro‑Scale

One exciting frontier is laser-patterned micro-magnets: manufacturers use ultrafast lasers to carve precise poles into SmCo or NdFeB, creating micro-rotors and actuators with sub-10 μm features. Another breakthrough? Wafer‑scale micromagnets with sputtered NdFeB layers, patterned with micrometer accuracy across thousands of chips.

These advanced fabrication techniques enable micro‑motors to deliver improved power density, precision, and reliability – all while shrinking down to meet modern design demands.

Real-World Applications of Micro-Magnets

- Medical & surgical devices: Ultra‑compact, efficient micro‑motor actuators fit within surgical drills or capsule endoscopes.

- Consumer electronics, such as earbuds and cameras: Utilize tiny haptic motors that rely on micro-magnets for precise vibration patterns.

- Microsystems & robotics: Micro linear actuators in micro-robots utilize minuscule magnets to convert electrical energy into motion with exceptional accuracy.

These magnets can be shaped into rings, tiles, trapezoids, or assembled into Halbach arrays, depending on the performance needs. Manufacturers are also developing thin-film and wafer-based micro-magnets via sputtering or laser machining, which integrate seamlessly onto MEMS platforms.

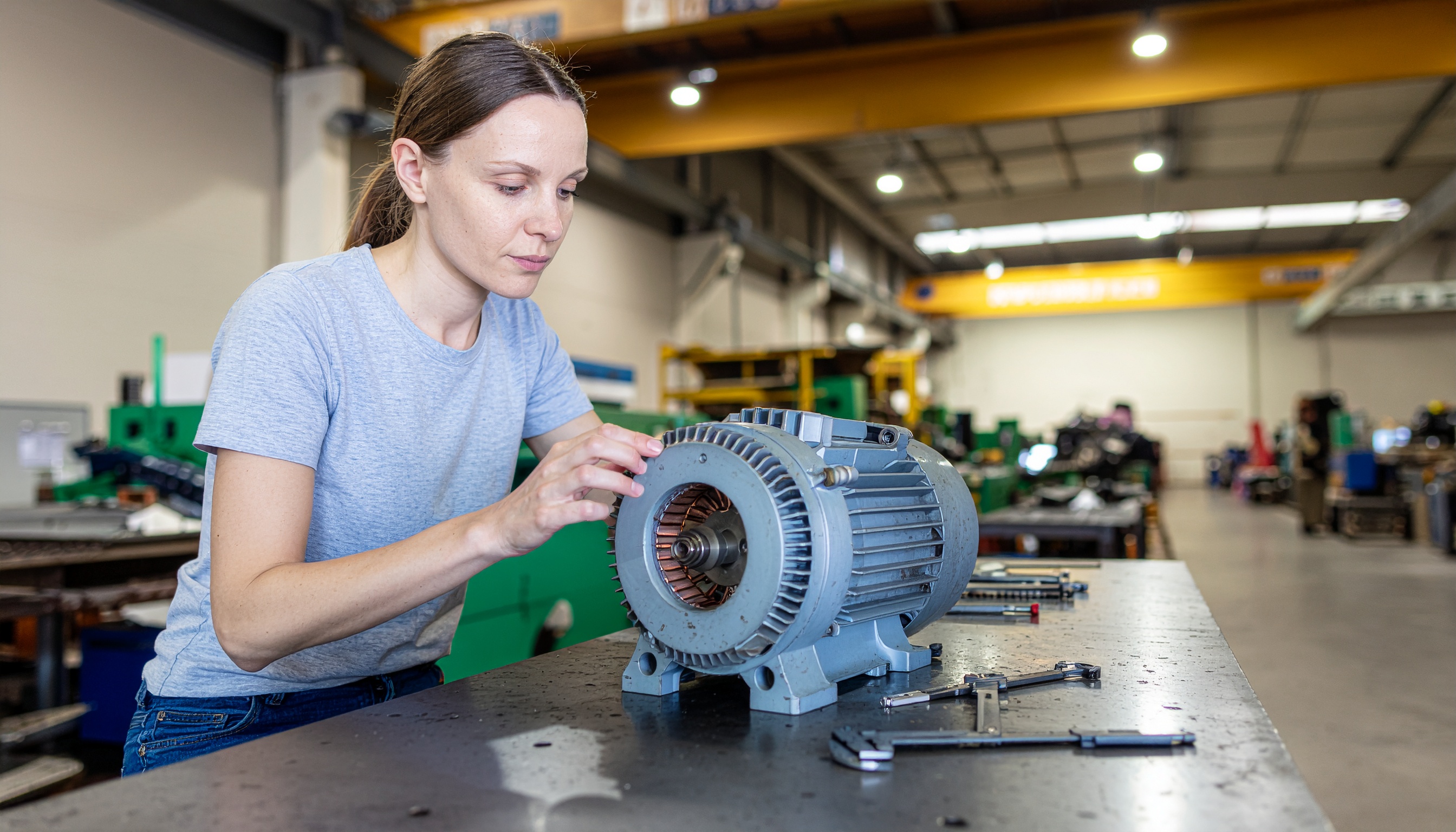

Design Challenges & Solutions

Working at a micro‑scale isn’t easy. Engineers must manage:

- Thermal stresses: Laser machining or high-speed operation introduces heat; choosing SmCo or applying thermal coatings helps stability.

- Tolerances: Aligning magnets and coils with sub-0.1 mm accuracy is crucial to prevent efficiency losses.

- Manufacturing integration: Incorporating magnets into MEMS via sputtering, electroplating, or laser welding must harmonize with standard fabrication steps.

BJA Magnetics addresses these challenges by providing tight-tolerance micro-magnet builds with options for custom coatings, materials, and geometries – ideal for demanding micro-motor designs.

As devices continue to shrink, micro‑magnet-enabled micro‑motors will only become more critical. Expect to see:

- MEMS motor arrays: enabling ultra-slim, multi‑axis actuators in compact packages.

- Laser‑fabricated Halbach drives: for highly efficient micro‑rotors.

- Room-temperature magnetic MEMS: combining micro‑magnets with coils for precise actuation in ultra‑small sizes.

Micro‑magnets may be tiny, but in micro‑motor design, they’re transformative. From powering surgical drills to tiny haptic actuators, they deliver compactness, power, and precision.

With advanced fabrication, tight tolerances, and tailored coatings, BJA Magnetics’ Micro‑Magnet™ is positioned to drive the next generation of micro‑motor innovation. In a world where every micron matters, these magnets pack a punch far beyond their size. Contact BJA Magnetics to get started!