Custom Assemblies: Engineered for Precision and Reliability

In complex systems across aerospace, medicine, and automation, a simple magnet is rarely enough. True performance comes from engineered solutions where magnets are integrated into a larger whole. These custom magnetic assemblies are the hidden engines of innovation, delivering precise force, sensing, and motion control in the most demanding environments.

For any engineer or designer, understanding the journey from a design concept to a finished assembly is critical for ensuring reliability, efficiency, and performance. This guide breaks down the essential steps in the manufacturing process, revealing how a collaborative approach transforms raw materials into powerful, application-specific solutions.

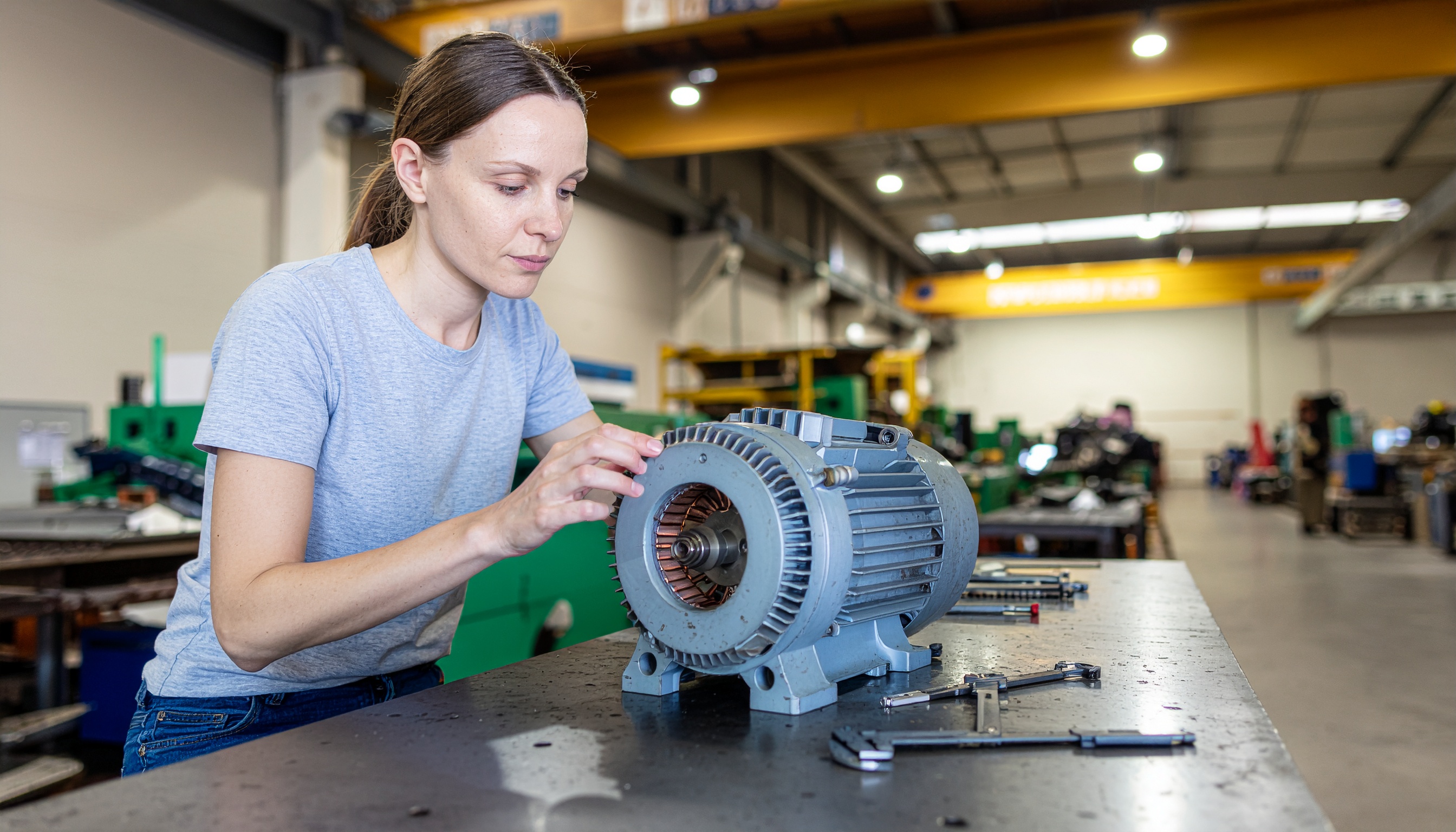

1. Collaborative Design & Engineering

The foundation of any successful custom magnetic assembly is a deep understanding of how it will be used. Early in the process, engineers work closely with your team to define performance goals, including magnetic strength, size constraints, operating environment, and integration challenges. Rather than relying on generic specifications, the focus is on understanding how the assembly will function in real-world conditions.

Advanced 2D and 3D magnetic modeling tools are then used to simulate magnetic fields, forces, and interactions. This upfront analysis helps identify potential issues early, reducing design revisions later and ensuring the final assembly performs as intended.

2. Material Selection & Specification

Magnets are available in a wide range of materials, each with distinct performance characteristics. Selecting the right magnet material and grade is critical to achieving the desired balance of strength, temperature resistance, and durability. Common considerations include:

- High-energy materials for compact, powerful assemblies

- Temperature-stable materials for high-heat environments

- Corrosion-resistant options for challenging operating conditions

In addition to magnet material, engineers also evaluate coatings, housings, and structural components to protect the assembly without compromising magnetic performance.

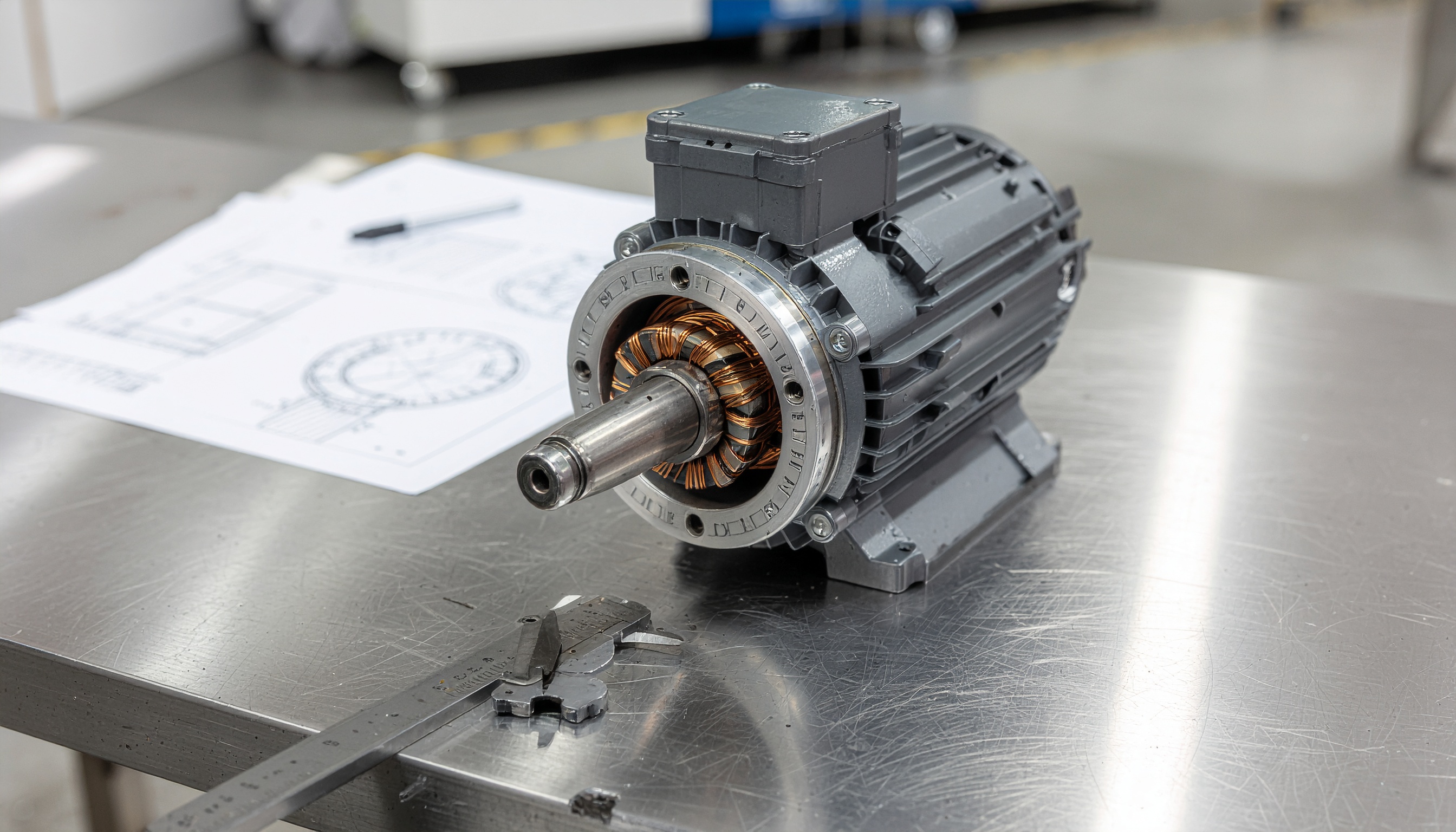

3. Precision Manufacturing

Once the design and materials are finalized, manufacturing begins. This stage transforms engineered concepts into reliable, repeatable components:

- Machining and forming: Magnet components and housings are produced to tight tolerances to ensure proper alignment and fit.

- Assembly and bonding: Magnets may be bonded, press-fit, overmolded, or mechanically retained, depending on the application and performance requirements.

- Magnetization: Assemblies are magnetized after assembly to ensure the magnetic field orientation and strength match the design intent.

- Inspection and testing: Each assembly undergoes dimensional checks and magnetic performance testing to confirm it meets all specifications.

Precision at this stage is essential for applications where consistency and reliability are non-negotiable.

4. Quality Assurance & Documentation

Quality systems play a critical role in the manufacturing of custom magnetic assemblies. Certified processes ensure consistency, traceability, and repeatability from prototype through production. Detailed documentation supports regulated industries by providing traceability of materials, inspection records, and test results.

This structured approach reduces risk, improves reliability, and supports long-term product performance.

5. Integration Support & Delivery

The final step is ensuring the magnetic assembly integrates smoothly into your system. Support may include guidance on installation, handling, and alignment, as well as packaging designed to protect magnetic components during shipment.

Custom magnetic assemblies are far more than magnets joined together; they’re engineered solutions designed for specific performance goals. Understanding the manufacturing process helps designers make informed decisions that improve reliability, efficiency, and product lifespan.

With an experienced partner, that process becomes collaborative, efficient, and focused on delivering results that perform in the real world. Contact BJA Magnetics today to get started!