Why Magnetic Testing Matters More Than Ever

In high-performance industries – ranging from aerospace and robotics to medical devices and industrial automation – quality is non-negotiable. Precision matters. Safety matters. And most importantly, trust in your components matters. That’s why, at BJA Magnetics, rigorous testing is at the heart of everything we do.

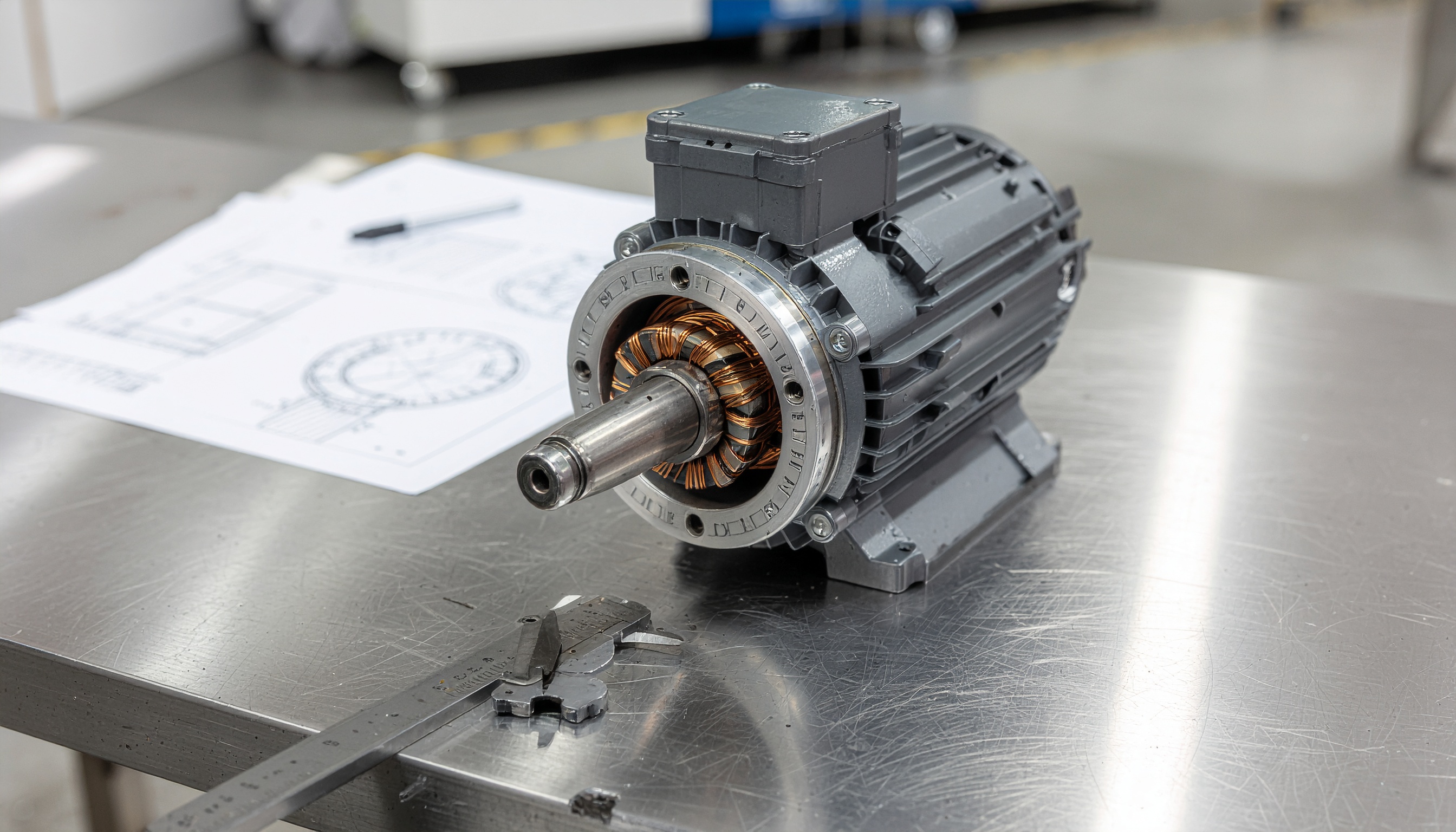

Magnetic components might be small, but they often serve critical roles. Whether it’s a magnet driving propulsion in an electric aircraft or a component used in surgical equipment, any deviation from expected performance can result in system failures, safety risks, or costly downtime. Testing isn’t just good practice, it’s essential.

1. Ensure Reliability from the Start

Magnetic materials and assemblies can behave differently depending on their grade, geometry, and application environment. A magnet that looks identical to another may perform very differently in the field if not properly aligned or magnetized.

That’s why we use advanced magnetic testing methods – like Helmholtz coils, fluxmeters, and Gauss meters – to confirm specifications such as magnetic moment, flux, and field direction before components leave our facility.

When you work with BJA, you’re not just getting a part. You’re getting a verified, tested, and documented solution tailored to your performance requirements.

2. Enhance Product & End-User Safety

In medical and aerospace applications, precision isn’t just a nice-to-have; it’s a life-or-death factor. For example, a surgical navigation system that relies on magnetically guided instruments must operate with incredible accuracy. Even minor inconsistencies in magnet orientation or strength can compromise the entire system.

Through strict testing protocols and adherence to standards like AS9100D, ISO 9001:2015, and ISO 13485:2016, BJA ensures that every magnet meets its performance criteria and supports safe, reliable operation in mission-critical environments.

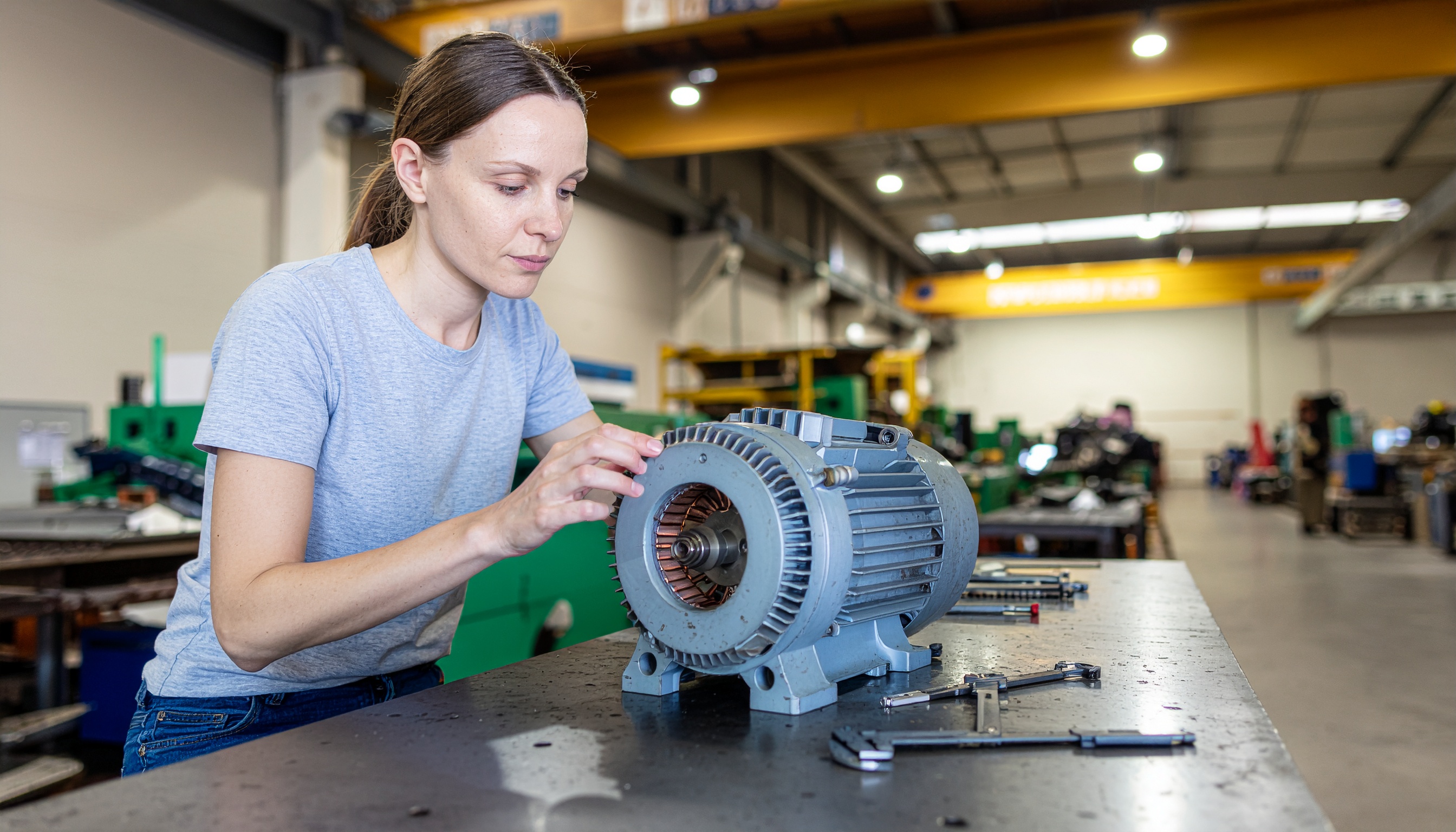

3. Reduce Downtime & Improve Efficiency

Undetected flaws in a magnetic assembly can lead to rework, production delays, or product recalls – issues that are expensive and time-consuming. With proper testing during production and final inspection, manufacturers can avoid these pitfalls and streamline their processes.

Our magnetic testing services are designed to detect even the smallest irregularities, allowing for corrections long before assembly or shipment. The result? Fewer disruptions, lower long-term costs, and greater confidence in your supply chain.

4. Deliver Transparency & Accountability

Today’s engineers, designers, and procurement teams demand more than assumptions – they want data. Testing offers tangible proof that a component meets its design requirements.

BJA provides detailed testing documentation and traceability for every part we ship, giving our customers clear insight into the quality they’re receiving. That level of transparency builds long-term trust and strengthens collaboration.

5. Support Customization & Innovation

When you’re developing next-generation technology, you need partners who can deliver custom components backed by reliable data. Our testing capabilities allow us to support complex design challenges, like shaping unique magnet configurations, verifying multi-pole orientations, or tuning magnetic field strengths for highly specialized applications.

In short, magnetic testing doesn’t slow innovation; it accelerates it. And at BJA Magnetics, we believe that testing isn’t a final step; it’s a continuous commitment. For us, it’s about protecting your reputation, enhancing your product’s performance, and enabling you to push boundaries with confidence. Explore our magnetic testing services to learn how we can help ensure the quality and performance of your next project. Contact BJA Magnetics to get started!